FEATURED PROJECT

Lakewood Village

RENCO’s first completed building in the United States and a celebrated breakthrough in construction technology.

SPEED

This 3-story, 4 building complex was fully erected and assembled in

less than 8 weeks.

EFFICIENCY

11 non-traditionally trained construction workers were all that was needed

to complete this job.

COST EFFECTIVE

This build saved approximately 20% of the duration and cost, compared to conventional hurricane

zone-type concrete.

FEATURED PROJECT

Lakewood Village

RENCO’s first completed building in the United States and a celebrated a breakthrough in construction technology.

SPEED

This 3-story, 4 building complex was fully erected and assembled in less than 8 weeks.

EFFICIENCY

11 non-traditionally trained construction workers was all that was needed to complete this job.

COST EFFECTIVE

This build saved approximately 20% of the time and cost over conventional hurricane zone-type concrete.

TESTIMONIAL

“As a partner in the first demonstration project to utilize RENCO’s materials, we have seen firsthand just how revolutionary these products are,” Dezer stated. “Given the advantages of these materials over traditional structural products, we believe Renco may change the way real estate developments are constructed in the future”

GIL DEZER

DEZER DEVELOPMENT

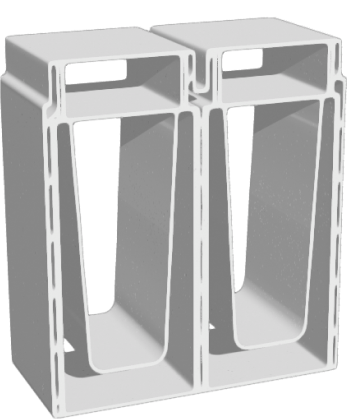

Renco MCFR

(Mineral Composite Fiber Reinforced)

RENCO’s proprietary MCFR weaves together repurposed glass fibers, resin, and limestone into a powerful composite that is substantially strong, extremely economical, and finishes in a fraction of the time.

ONE

Molded blocks that interlock like LEGO bricks create entire structures

THREE

MCFR is completely water, mold and even termite resistant

TWO

Rated to withstand Category 5 hurricane force winds

FOUR

ANSI certified for structural performance

CUSTOM FORM

Similar to injection molding, any shape necessary may be formed from the composite compound (e.g. – blocks, roof beams, joist or flooring).

EASILY BONDS

MCFR is fused together with methyl methacrylate, a bonding agent that is currently already being used in trucking, aerospace and marine products.

ECO FRIENDLY

Crafted from eco-friendly, raw and recycled materials, this significantly reduces RENCO’s carbon footprint compared to conventional construction practices.

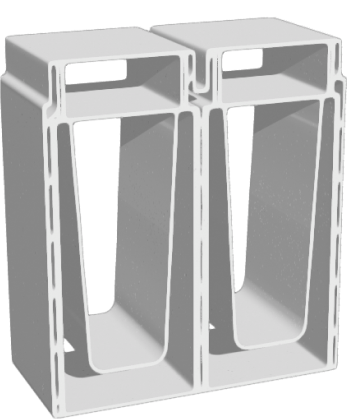

Renco MCFR

(Mineral Composite Fiber Reinforced)

RENCO’s proprietary MCFR weaves together repurposed glass fibers, resin, and limestone into a powerful composite that is 23 times stronger than concrete, extremely economical, and finishes in a fraction of the time.

ONE

Molded blocks that interlock like LEGO bricks create entire structures

TWO

Can withstand 275 MPH winds and is rated to withstand a Category 5 hurricane

THREE

MCFR is completely water, mold and even termite resistant

FOUR

ANSI certified for structural performance

CUSTOM FORM

Similar to injection molding, any shape necessary may be formed from the composite compound (e.g. – blocks, roof beams, joist or flooring).

EASILY BONDS

MCFR is fused together with methyl methacrylate, a bonding agent that is currently already being used in trucking, aerospace and marine products.

ECO FRIENDLY

Crafted from eco-friendly, raw and recycled materials, this significantly reduces RENCO’s carbon footprint compared to conventional construction practices.